2026 Best Pre Engineered Buildings for Modern Construction Solutions?

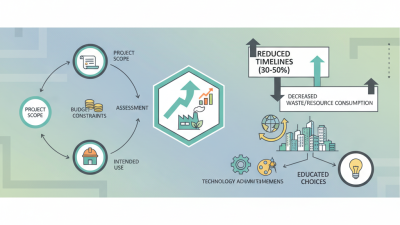

In the realm of modern construction, pre engineered buildings (PEBs) have emerged as an innovative solution. These structures offer flexibility, efficiency, and cost-effectiveness. As we explore the best PEB options for 2026, it is essential to consider various factors.

PEBs are designed with the latest technology. They can be customized to meet specific needs. For instance, they often require less time to construct compared to traditional buildings. Yet, one must reflect on potential drawbacks. Installation challenges may arise, depending on site conditions.

Additionally, sustainability remains a concern. While PEBs are often more energy-efficient, the production process still impacts the environment. Striking a balance between modern needs and ecological considerations is crucial. These factors will shape the future of pre engineered buildings in construction.

Emerging Trends in Pre-engineered Buildings for 2026

The construction industry is evolving rapidly. Pre-engineered buildings are at the forefront of this change. They offer flexible design options and faster assembly times. In 2026, we can expect innovative materials to gain popularity. Lightweight composites and eco-friendly materials will dominate the market. These advancements could lead to more sustainable structures.

Energy efficiency is another key trend. Solar panels and energy-efficient designs will become standard. More builders are integrating renewable energy solutions into their plans. This shift represents a move toward greener construction. However, challenges remain in maintaining cost-effectiveness while adopting new technologies.

Building codes are adapting to these trends as well. Regulations will likely emphasize sustainable practices. There may be a struggle to balance innovation with compliance. Industry professionals must stay informed and flexible. The future of pre-engineered buildings holds great promise, but the path won’t be without hurdles.

Key Advantages of Pre-engineered Structures in Modern Construction

Pre-engineered buildings are a growing trend in modern construction. They offer several advantages that cater to the needs of today's builders and developers. A report from the Global Pre-engineered Building Market (2022) shows that this market is projected to grow at a CAGR of 10.5% through 2028. This growth is driven by the need for quick and efficient construction methods.

One key advantage of pre-engineered structures is speed. These buildings can be erected in a fraction of the time compared to traditional methods. For instance, a typical pre-engineered facility can be completed in just 50% of the time, significantly reducing labor costs. Moreover, they utilize less material, which leads to lower waste. A report from the Green Building Council highlights that one building project can reduce waste by up to 30% when using pre-engineered techniques.

Cost efficiency also plays a significant role in their popularity. Pre-engineered buildings often fall within 10 to 20% cheaper than conventional structures. This affordability makes them attractive for small to medium enterprises looking for quality without breaking the bank. However, these structures can face limitations in design flexibility and customization. Some builders may find them too rigid for unique architectural visions. While pre-engineered buildings are innovative, they may not suit every project, sparking ongoing debate within the industry.

Key Advantages of Pre-engineered Structures in Modern Construction

Popular Materials Used in 2026 Pre-engineered Building Designs

As we move toward 2026, pre-engineered buildings are gaining traction in modern construction. These buildings often incorporate materials that are not only cost-effective but also environmentally friendly. Steel frames are a popular choice for their strength and durability. They can be customized and easily assembled, saving time on construction sites.

Another material making waves is insulated metal panels. These panels provide excellent thermal performance and are lightweight. They also come in a variety of finishes. This flexibility allows architects to create visually appealing structures without compromising on efficiency.

Wood is also making a comeback, particularly in sustainable designs. Engineered wood products are strong and reduce waste. However, some may argue about the carbon footprint of wood production. The balance between aesthetics and sustainability is not always easy to strike. As we adapt to new materials, the challenge will be to refine our choices for better long-term outcomes.

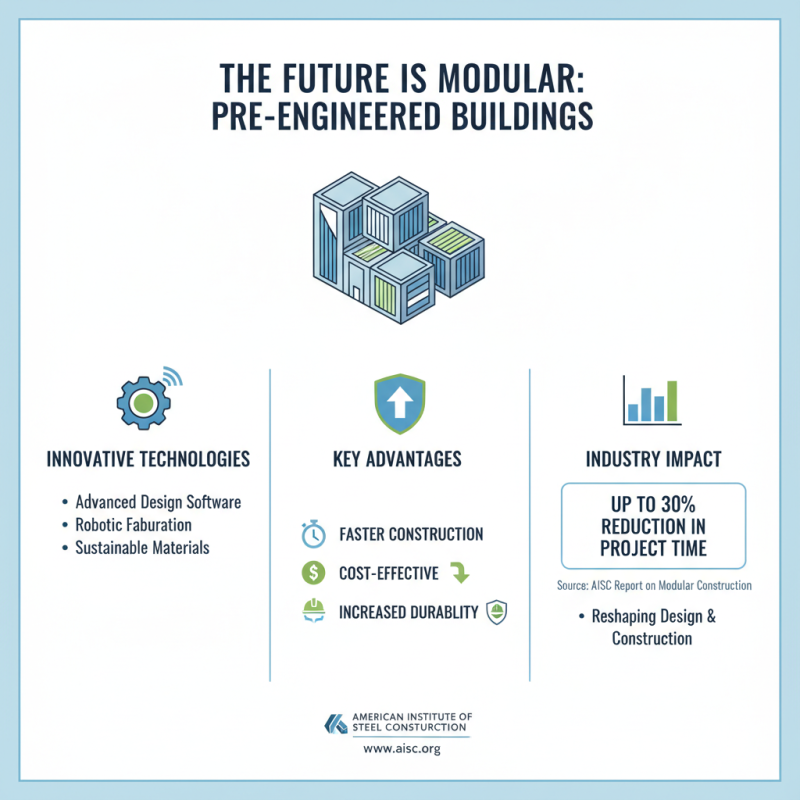

Innovative Technologies Revolutionizing Pre-engineered Construction

Pre-engineered buildings are gaining popularity due to innovative technologies. These advancements are reshaping how structures are designed and constructed. According to a recent report by the American Institute of Steel Construction, the use of modular construction methods can reduce project times by up to 30%. This speed is essential in today’s fast-paced construction environment.

Digital tools like Building Information Modeling (BIM) optimize the design process. BIM allows for precise planning and reduces waste. It enhances collaboration among architects, engineers, and contractors. A study by McKinsey & Company reveals that effective use of BIM can improve project efficiency by 20%. The integration of augmented reality (AR) is also noteworthy. AR helps in visualizing projects before they start. This technology bridges gaps between ideas and reality.

Tips: Consider energy efficiency as a priority when selecting materials. Sustainable choices enhance long-term value. Keep in mind that new technologies may require training. Invest time to upskill your team. It's essential to remain adaptable. Not every tech implementation will be a perfect fit for all projects.

Case Studies: Successful Modern Pre-engineered Building Projects

Pre-engineered buildings have emerged as a popular choice for modern construction. They combine efficient design and lower costs. Several projects serve as excellent case studies. One notable example features a community center built in a short timeframe. The design utilized modular components, reducing waste and labor hours. Finishing this project in just six months stood out for the team.

In another instance, a warehouse made of pre-engineered materials was constructed swiftly. This building minimized delays and ensured on-time delivery. However, the project faced challenges with site preparation. Poor soil conditions posed issues that required extra planning and resources. The team learned the importance of pre-site surveys to avoid future setbacks.

These case studies highlight the flexibility and efficiency of pre-engineered buildings. Yet, they remind us that careful planning is key. While the benefits are clear, potential obstacles must be addressed. If project teams anticipate such challenges, it can lead to smoother operations and better results in the future.

2026 Best Pre Engineered Buildings for Modern Construction Solutions

| Project Name | Location | Size (sq ft) | Completion Year | Key Features |

|---|---|---|---|---|

| Urban Sports Complex | New York, NY | 120,000 | 2026 | Sustainable materials, Multi-sport facilities |

| Green Assembly Hub | San Francisco, CA | 150,000 | 2025 | Energy-efficient design, Green roofing |

| Tech Innovation Center | Austin, TX | 200,000 | 2024 | Collaborative spaces, Modular design |

| Community Health Center | Chicago, IL | 80,000 | 2026 | Patient-centered design, Eco-friendly materials |

| Industrial Warehouse | Atlanta, GA | 250,000 | 2025 | High ceiling, Automation-ready |

Related Posts

-

Why Pre Fab Building is the Future of Sustainable Construction

-

How to Choose the Best Pre Fab Building for Your Next Project

-

10 Essential Tips for Choosing Residential Construction Contractors

-

Top Benefits of Using Steel Structures in Modern Construction

-

2025 Top 10 Innovative Construction Materials Revolutionizing Building Industry

-

10 Best Advantages of Using Steel Structure Buildings for Modern Construction